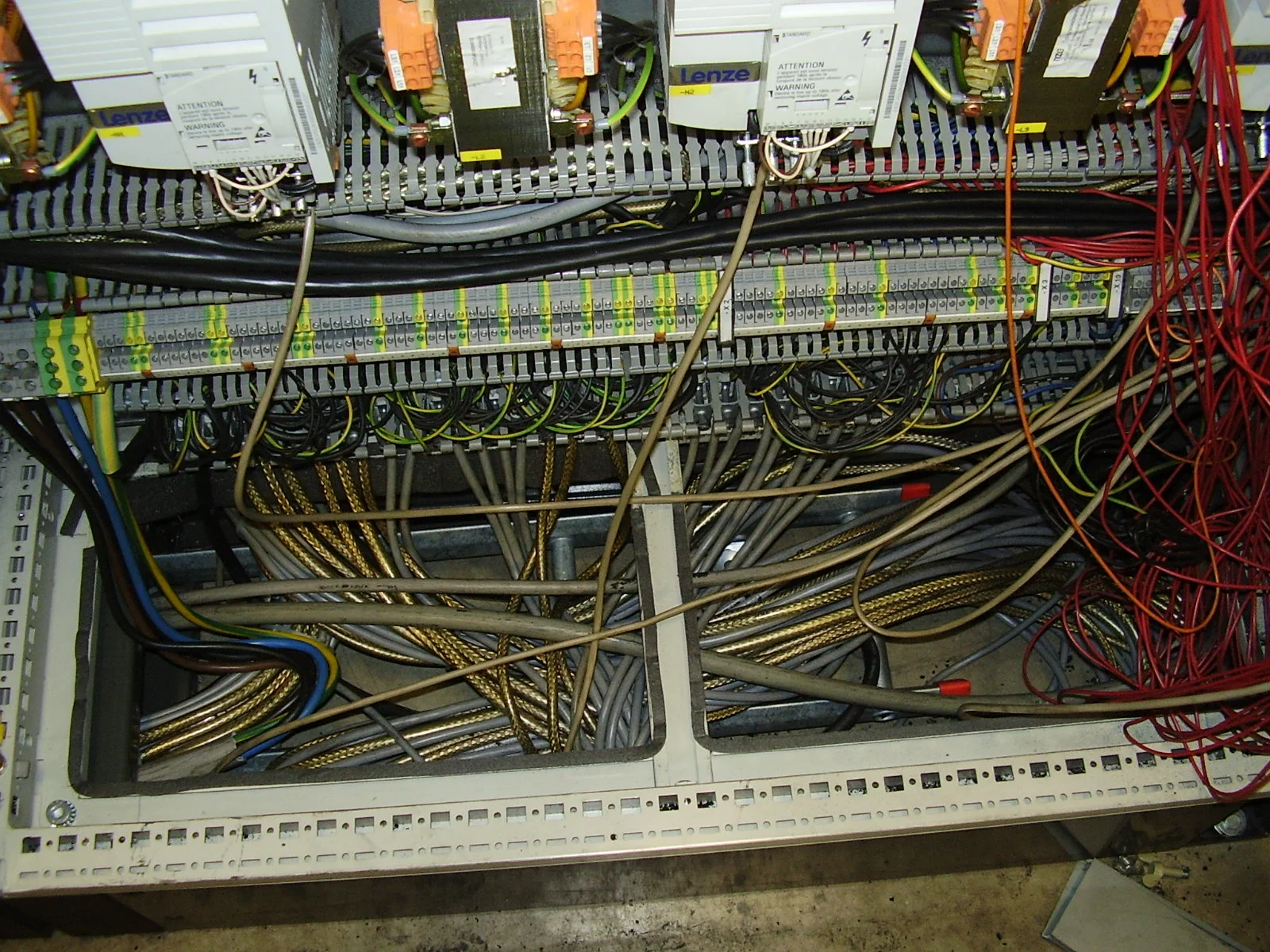

Switchboards are the nerve center of any electrical system. Without regular maintenance, dust, grease or corrosion can cause unnoticed damage resulting in expensive downtime. Professional control cabinet cleaning is therefore not a superfluous luxury, but an investment in safety and operational reliability.

At Flancco, we use dry ice blasting to thoroughly clean switchboards, distribution boards, control cabinets and delicate components without any risk of damage. The method is dry, chemical-free and non-conductive – thus 100% safe for electrical applications and control cabinet cleaning.

Electrical installations, such as switchboards, computers and sensitive electronic components, are critical to the reliable operation of industrial and commercial processes. Dust, dirt, grease and moisture can accumulate and lead to overheating, short circuits and loss of performance. Traditional cleaning methods using water or chemical solvents pose risks such as corrosion and damage to delicate components.

Dry ice blasting is a safe, dry and non-conductive method that cleans electronic equipment without risk of damage or failure. This method prevents accumulation of dust and contaminants and extends the life of your electrical systems.

Where and when is switchgear cleaning relevant?

Flancco offers an innovative and sustainable solution for cleaning control cabinets, computers and electrical components. Our dry ice blasting technology guarantees safe and effective cleaning of control cabinets without risk of damage.

Learn more about control cabinet cleaning, importance of making a control cabinet dust-free by dry ice cleaning here.

Read all about the technology behind our method on the dry ice blasting page, or request a free quote for a customized maintenance plan.

Flancco offers an innovative and sustainable solution for preventive cleaning of switchboards, computers and electrical components. Our dry ice blasting technology guarantees safe and effective cleaning without risk of damage. Contact us for a customized maintenance solution that keeps your electrical systems functioning optimally!

Flancco is part of XL Group Vlaanderen.